Ope! 404 Page Not Found

The page you were looking for has been moved or deleted.

The page you were looking for has been moved or deleted.

Introducing the ColdOne™ Portable Kegerator, the hassle-free solution for enjoying your favorite ice-cold beverages wherever you go. Craft beer, seltzers, or mixed drinks – no matter your preference, ColdOne™ keeps them chilled for days on end, making it the ultimate setup for beverage enthusiasts like you.

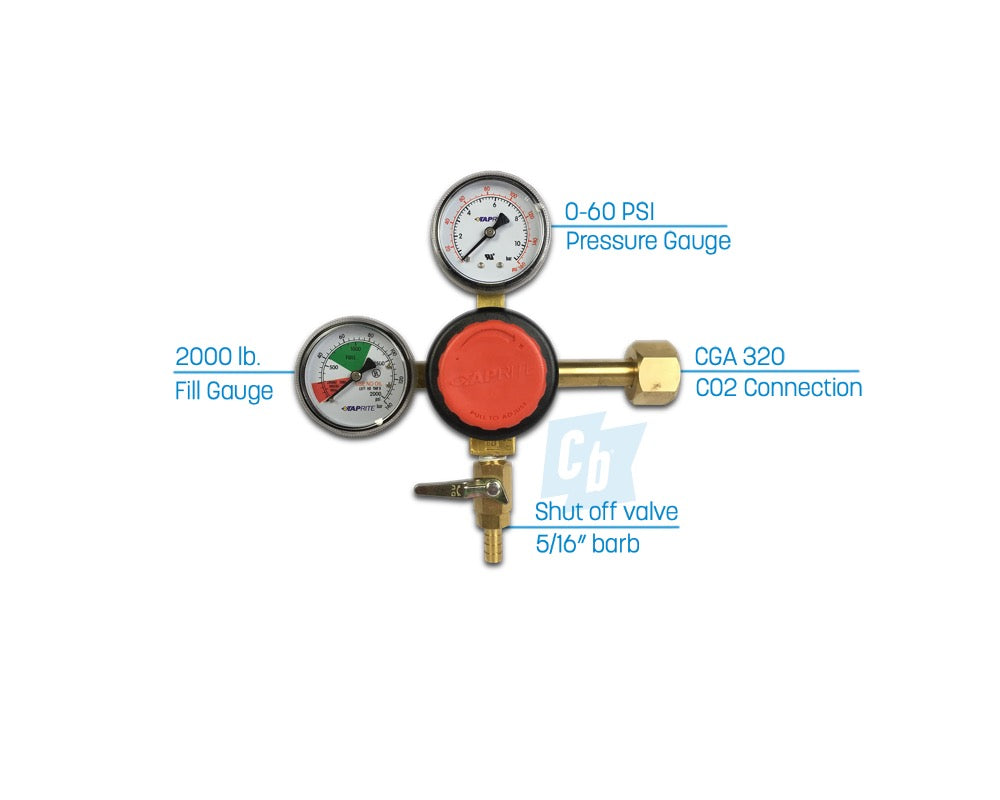

No more relying on secondary cooling sources or piles of ice, because ColdOne™ is self-contained and requires no external help. With its impressive capacity of up to 2 gallons (16 pints), it keeps your beverages icy cold for up to 5 days. Plus, our CO2 cartridges ensure a constant supply of carbonation, allowing you to serve up to 4 kegs before needing to change cartridges. From the first pour to the last, your drinks will stay refreshingly fresh.

With ColdOne™, the possibilities for pouring are endless. Take it to your local brewery and fill it up like a growler, or create delightful mimosas for Sunday brunch. Unleash your mixology skills and craft potent cocktails like Jack and Coke or Margaritas with ease. Whether it's a gathering or a party, ColdOne™ ensures your guests are always treated to the perfect cold beverage of their choice.

But ColdOne™ is more than just a portable kegerator – it's a statement of your appreciation for quality beverages. Its sleek design and user-friendly dispensing system will make you the envy of your friends and family. And if you're searching for the ideal gift for a beer, seltzer, or mixed drink lover, look no further.

So why wait any longer? Embrace the ColdOne™ experience and enjoy the perfect beverage dispensing system for yourself. Say cheers to ice-cold and refreshing drinks that will elevate any occasion. Get your ColdOne™ today and take your beverage enjoyment to a whole new level.